Manufacturing and Engineering Courses

|

Intro to Engineering Design - HTC385 (Semesters)

Times Offered: 12:30pm - 2:03pm, Fall/Spring *New Hampshire Scholars Eligible Level I students in our Engineering/Manufacturing pathway will have the opportunity to design, develop, and gain skills in the development of manufactured products using the latest solid modeling software and virtual CNC machinery.

Amatrol eLearning Technical Training courses are widely used. Students are introduced to the engineering design process, applying math, science, and engineering standards to identify and design solutions to a variety of real-world problems. Students work both individually and as a team to develop and document design solutions using engineering notebooks. This course is suggested for grades 10 and above but freshmen may apply with approval of their guidance office. Course Highlights:

Course Outcomes:

Take a Virtual Tour of the Engineering Classroom

|

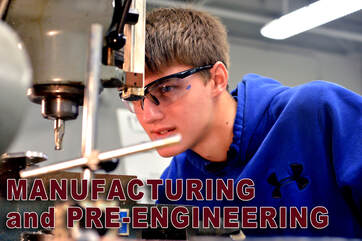

Pictured above; Connor Craigue, 2017 U.S. Presidential Scholar in Career and Technical Education.

Enduring Understandings:

Essential Questions:

Take a Virtual Tour of the Manufacturing Lab

|

Level II Options for Manufacturing/Engineering

|

Computer Integrated Manufacturing – HTC415

Times Offered: 9:00am-10:30am *New Hampshire Scholars Eligible Level II students will work with Advanced CNC set-up and operations, Computer Aided Manufacturing (CAM) operations, operational management skills and current manufacturing principles such as Lean production flow and inventory, 5-S workplace organization - Amatrol eLearning Technical Training courses are widely utilized. Students have the opportunity to receive college credits Project Running Start, and the course articulates with Central & Southern Maine Community Colleges. In addition, students can earn industry-recognized certifications such as; CSWA-Certified SolidWorks Associate & Professional Level, Master CAM-Associate Level, MSSC-Certified Production Technician and Tooling University Certificates.

Enduring Understandings:

Essential Questions:

Course Highlights: Students utilize advanced features of SolidWorks Computer Aided Drafting software to design a working product and blueprint for manufacturing.

Course Outcomes

|

Principles of Engineering – HTC415

Times Offered: 10:30am-12:03am *New Hampshire Scholars Eligible Through problems that engage and challenge, students explore a broad range of engineering topics, including mechanisms, the strength of materials and structures, automation, and motion. Students develop skills in problem solving, research, and design while learning strategies for design process documentation, collaboration, and presentation. Students develop problem-solving skills using SolidWorks computer aided-drafting software with an emphasis placed upon the concept of developing a 3-D model or solid rendering of an object. Amatrol eLearning Technical Training courses are widely used. State of the art computer hardware and software will be used to emphasize design development processes and computer aided drafting & design.

Enduring Understandings:

|